Inventory of Hazardous Materials Sampling Onboard Existing / new Ships

We, Constellation Marine Services LLC as independent ship and marine surveyors, often get instructions by our existing as well as by new clients to carry out IHM sampling onboard existing vessels. Recently one of our clients requested us to carry out IHM sampling as per class approved VSCP (Visual sampling & check Plan) on board the existing tanker vessel. Our Naval Architect/IHM expert upon receipt of instruction boarded at Fujairah anchorage, UAE.

PURPOSE OF IHM (INVENTORY OF HAZARDOUS MATERIALS):

1. To provide ship-specific information on the actual hazardous

materials present on board in order to protect human health

and safety.

2. To prevent environmental pollution at ship recycling

facilities

SCOPE OF THE WORK:

Sampling of Hazardous materials as per Class Approved VSCP Plan.

BACKGROUND:

There are two key legislations with respect to ship recycling

in the industry as below,

1. IMO Hong Kong Convention (HKC) SR/CONF/45.

2. European Union Ship Recycling Regulation (EU SRR) EC

No 1257/2013.

Hong Kong Convention contains six guidelines in total and

MEPC.269 (68) stands the guiding code for the development

of the Inventory of Hazardous Materials (IHM) under IMO.

IMO Hong Kong Convention (HKC) SR/CONF/45:

HKC will be applying to the vessels, operating in the marine

atmosphere, which are equal to or above 500 Gross Tonnage.

Merchant navy vessels and inland ships are excluded from

the scope. HKC has two key concerns,

1. Inventory of hazardous materials (IHM)

2. Endorsement of ship recycling facilities.

EU Ship Recycling Regulation (EU SRR) EC No 1257/2013:

The EU SRR has entered into force in 2013 and general application

had started at the end of year 2018. Same as the HKC, EU

SRR is applicable for ships, operating in the marine atmosphere,

which are equal to or above 500 Gross Tonnage. Merchant

navy vessels and inland ships are excluded from the scope.

The EU SRR has two key concerns as similar as HKC convention

1. Inventory of hazardous materials (IHM)

2. EU List of approved ship recycling facilities.

PREPARATION OF SAMPLING:

Requested plans/drawings of General arrangement, Engine room arrangement plan, Capacity Plan & safety plan had been provided as requested by attending IHM experts of M/s. Constellation Marine Services LLC and upon receipt same have been assessed in detail of the applicability for the preparation of an IHM sampling onboard.

SAMPLING ONBOARD:

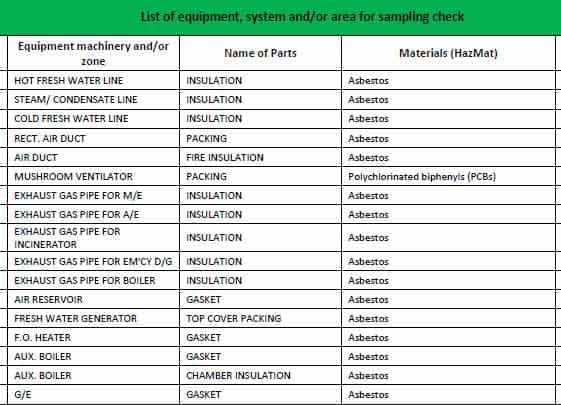

Sampling points were identified as per Class approved VSCP

(Visual Sampling and Check Plan). Samples were drawn from

locations/Sampling points as identical as mentioned in VSCP

with relevant hazardous materials. Following sampling procedure

had been followed onboard by IHM experts,

1. Photographs of sampling point/location had been taken

during sampling (Three pictures of each sampling)

(Pic 1: Sampling Location, Pic 2: Drawn sample in sampling

bag with location)

2. Using permanent marker unique sampling code (as per VSCP)

has been mentioned in the sampling bag.

3. Sample’s had been extracted from sampling point by using

appropriate tools like pliers, pocket knife. Drawn samples

were sealed in air sealing bag. After each samples drawn

tools were cleaned with wet wipes.

4. Limitations like access to sampling point, change/differ

of sampling location, sampling procedure from VSCP plan

had been mentioned in remarks column in VSCP.

5. Sampled locations had been marked in plans/drawings provided

(General arrangement, Engine room arrangement plan, Capacity

Plan & safety plan).

SPECIMEN OF SAMPLING LOCATION/POINTS ONBOARD:

GOING FORWARD:

Samples drawn onboard during sampling were sealed in air sealing bag and had been dispatched to a recognized lab for analysis.